*Plus VAT. Course can be viewed and edited for one year after activation. Price is per participant. Access data are personalized and may not be passed on.

Course format: #Spotlight

#Spotlight: Tool coating

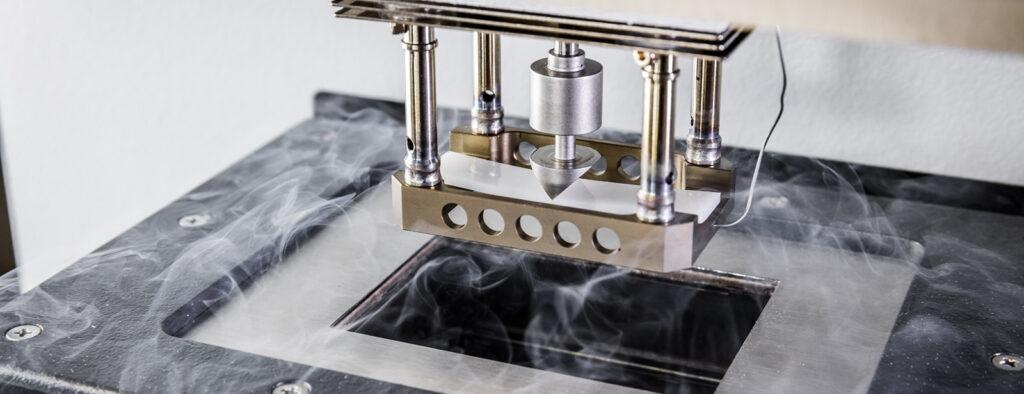

Tool surfaces in injection molding are exposed to harsh conditions. They must withstand high temperature and pressure loads and be as resistant as possible to wear and attack by corrosive substances. Targeted coating of the highly stressed and often very cost-intensive tools can produce higher-quality injection molded components and effectively increase the service life of the tools. By extending maintenance intervals, improved resource and material efficiency is also achieved.

Get an overview of coating technologies and properties of surface modifications and learn which coating can help you achieve increased productivity and reduced scrap. The session will be rounded off with an insight into the latest research results from the non-profit KIMW Forschungs-GmbH.

Objectives: The course will provide an overview of coating technologies and coating systems as well as their use in toolmaking and manufacturing. In-depth explanations are given on how tool surfaces can be specifically protected against wear, while the interested party also gains an insight into the research of the non-profit KIMW Forschungs-GmbH.

Target group: The seminar is aimed at people and employees involved in the planning, projection and manufacture of injection molds or related tools, as well as people from the areas of tool design and toolmaking and anyone who wants to learn more about tool coatings.

Official online course of the Kunststoff-Institut Lüdenscheid

Official online course of the Kunststoff-Institut Lüdenscheid